Before Bentham Pottery

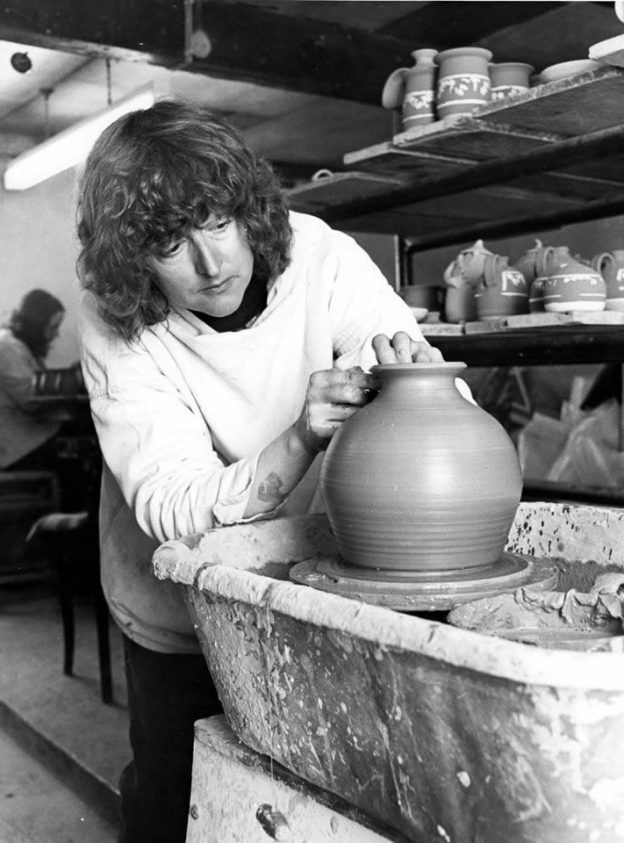

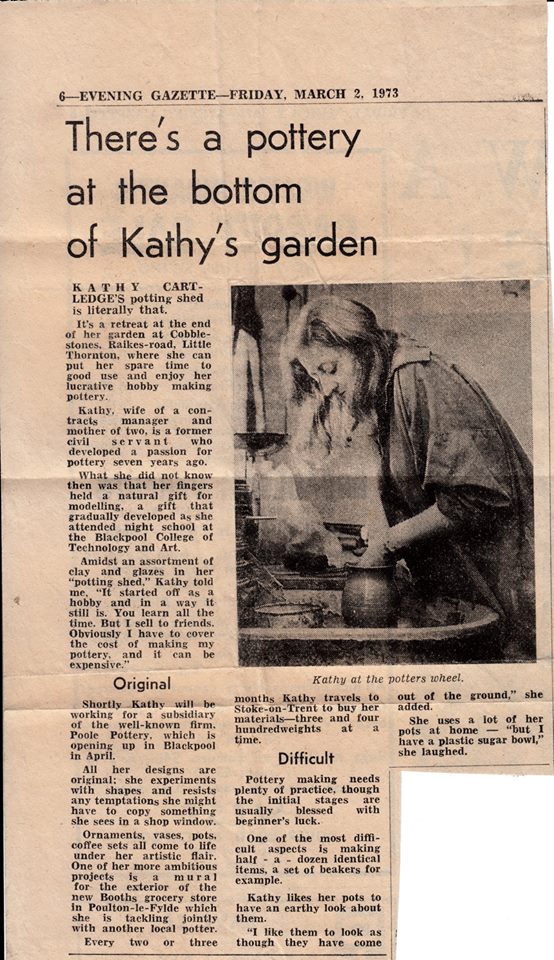

My mum, Kathy, worked in the tax office in Preston in the 1950s and 60’s. When she was on maternity leave with my brother in 1965, her mum (my Gran) said that she would look after the baby for one afternoon a week, so Kathy could go and further her education by joining a class at Blackpool technical college. The class she decided to do was pottery and she quickly became very addicted to this new medium! She became so addicted in fact that with the help of my dad, Barrie, she set up a small scale pottery in their garage in Thornton Cleveleys. At this time she was mainly making pots for friends and experimenting with techniques and glazes.

Kathy went back to work at the tax office on a part-time basis. One morning she went into work and her boss asked her to come into his office. Her boss surprisingly asked Kathy if she had any enemies. Kathy shocked by this question replied that she didn’t think she had. Her boss then went on to explain that somebody had reported that she had set up a pottery in her back garden and were the tax office aware of this new enterprise? Her boss then went on to explain that legally they would have to open a case file on her to investigate this claim, which you can imagine was not a great thing to happen to someone working at the tax office. Her boss then went on to advice Kathy to get an accountant and legally register the pottery as a business. Kathy followed her boss’s advice and did this; and continued making pots on a part time basis. Nothing else arose from this event, until 12 months later, when Barrie (my dad) got a large income tax refund based upon the losses that Kathy was making running a pottery! So in a way the person who had reported her to the tax office had done her a favour. It also made Kathy think that if some unknown person thought she had a business that merited paying tax, then perhaps she could turn pottery into a paying business?

Kathy lost her job at the tax office. We have no idea if she lost her job due to the case file that had been opened on her. This forced her to become a full time potter. Her throwing technique improved and she started selling pots through craft shops, directly from her garage/workshop and at pottery parties (think Tupperware parties, but for pottery).

One day in the early 1970s a man came into the pottery and announced that he worked for Poole pottery and was setting up a branch of Poole Pottery in Blackpool, to be called the “Royal Lancastrian Pottery”. He wanted to know if Kathy would work there as a production thrower. As Kathy lived close to Blackpool, this was a good opportunity for her, so she decided to accept the position.

People on pottery courses are always impressed when I tell them that my mum worked as a production thrower at Poole Pottery. However the reality is, it was a shit job and the whole set up in Blackpool was badly run. When you are running your own pottery your working day is split between many different jobs, when you are working as a production thrower, all you are doing is throwing pots all day every day. Kathy found this particularly tiring and also she had to do this in front of all the tourists that were coming into the shop. On the plus side her throwing techniques and speeds came on in leaps and bounds. She was throwing 30-40 mugs per hour after a few months of working here. Some of the staff were not particularly skilled. Kathy remembers that the man responsible for firing the kiln turned it on overnight with the front door open. The effect of this was to warp the whole kiln, so that the door of the kiln could no longer be closed. Subsequent firings were made by filling the gap in the door with refractory bricks.

Kathy worked here for a couple of years, until 1976, when our whole family uprooted and moved to Low Bentham and to a whole new episode in our lives! I don’t think Poole Pottery in Blackpool lasted much more than 12 months after Kathy had left.

The Booths Mural

One important commission that occurred during these early years was instigated by Barrie.

In the early 70’s Barrie was involved with designing a heating system for a new Booths’ supermarket to be opened in Poulton-le-Fylde. On a whim Barrie wrote to the Managing Director of Booths and suggested that they should consider having a ceramic mural as a centre piece decoration in this new Poulton store. Much to Barrie’s surprise the Managing Director got back to him and said this was a great idea, more surprisingly still was the fact that he’d consulted with the architect and they wanted it on the shop front and to measure approximately 1 metre by 10 metres. Kathy worked on the design of the mural with fellow potter Ken Gunn. They came up with a sketch that was loosely based upon the Booths’ logo of the time which was a lion. Despite the sketch being quite abstract (it really is difficult to locate the lion in the finished mural) the design was approved and they got the go ahead to make it. The sketch was traced out onto tissue paper and then transferred onto slabs of clay, where 3D detail was then added.

Kathy got a few visits from members of the Booths’ family during the making of the mural. On one visit, she was told to remove and scale down some of the 3d elements, because they were concerned that people would use them as hand holds to climb onto the mural and so Kathy was cheated out of unintentionally producing one of the first artificial climbing walls in the U.K. On another visit a different member of the Booths’ family showed what can only be described as a lukewarm enthusiasm for the mural, saying that its purpose was just to cover up the very “ordinary” architecture.

Once all the panels of the mural were fired, Booths sent some wooden plywood panels to stick them onto. Barrie was apprehensive about how to stick the tiles to the wood. This was in the days before Gorilla Glue! He experimented with a few different glues before deciding to use a silicon based adhesive. He can remember being very worried that the vibrations from traffic on the road outside the stall might cause the tiles to fall off. He need not have worried, as the mural remained firmly stuck to the shop front of Booths for 45 years, until Booths sold the stall to Aldi in 2016 and relocated elsewhere in Poulton. I have since enquired about what happened to the mural. Booth’s response to this was:

“It appears from our estates manager that unfortunately we couldn’t remove it to keep it. So it went with the building when sold on. “

I sent an email to Aldi. They replied;

“We would advise to speak to Booths directly as this mural would have been their property prior to us building on the land.”

I find this a bit weird, as Booths had already told me that they had sold the building with mural to Aldi?

I found an article on www.visitpoulton-le-fylde.co.uk that said that Aldi knocked down the rear of the Booths store and converted it into a car park. However they kept the front of the store (which would have had the mural on) and converted it into a smaller shop that they intended to rent.

I looked on Google Earth and found that “Card Factory” is renting the shop. I emailed Card Factory. They didn’t reply.

I’ll be the first to admit that this is getting ever so slightly obsessive!

I looked on Google Earth again and noticed there is a butcher’s shop next to the original shop front. I rang them up. They told me that the mural had been put in a skip. They also told me a man called Greg, an ex-taxi driver who runs a business consultancy in Poulton, had some pieces of the mural. They then became a bit vague about Greg. I think they were worried that I was pursuing him for illicitly acquiring a historically important artefact!

I emailed a number of business consultancies in Poulton before finding Greg. Actually it’s Greg’s step son who runs the consultancy business.

Greg, it turns out, was rightly appalled that the mural was going to be thrown out, so he liberated some fragments of it from the skip, which are now on permanent display in his garden. I only hope that other people did the same thing!

So, sadly, it looks as though the bulk of the Booths mural is confined to the skip of important lost U.K. art works. However a few shards remain intact and perhaps provide a shadow of its once former glory!

The move to Bentham

My dad Barrie, was an active caver in the early 1970s and so it was he discovered the joys of the Yorkshire Dales, in particular the area around Ingleton, Clapham and Kirby Lonsdale.

Barrie was doing a plumbing related job on the outskirts of Kirkby Lonsdale sometime around 1975, when he went into a café and bought a copy of the Westmorland Gazette and saw an advert for a farm that was for sale in Low Bentham. He rang the estate agent and visited the farm and it was love at first sight. He went home and managed to persuade my mum, Kathy, that a move to Low Bentham was essential for our health, wellbeing and happiness. He also managed to persuade the company he worked for in Fleetwood to transfer him to an office they had in Lancaster, which would make for an easy commute from Low Bentham.

We moved into Oysterber Farm in July 1976, just in time for one of the better summers of the 20th century. We really thought we had moved to paradise. My parents threw the mother of all house warming parties, which is still discussed in some quarters of Low Bentham to this day (I remember spending a fair bit of time the next day joining the search for Billy Slee’s false teeth, which he had misplaced during the revelry). Barrie then went on to do what I have now witnessed a lot of cavers do who move closer to the Dales – he gave up caving. This worked out fine for me though, as when I started caving in the 80s, I inherited all his kit.

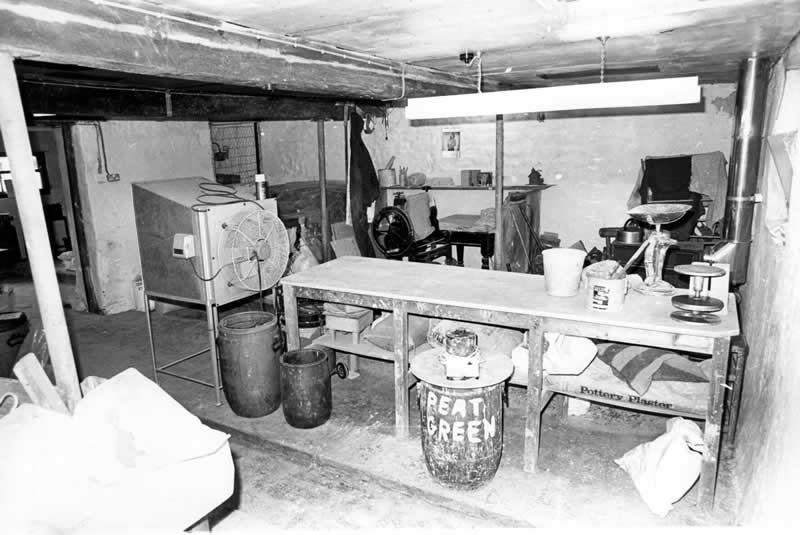

The pottery was uprooted from Thornton Cleveleys and reassembled in the cowsheds, chicken runs and milking parlour of Oysterber Farm. The kiln had to be craned into the cowshed through the roof (this was the kiln’s second, but not final, move). A wood burning stove was assembled in one of the rooms and was the only source of heating when the kiln wasn’t on. It must have been blinking freezing in the winter months. The pottery occupied 2 former cow sheds and one former chicken coop. Stairs led up to a hay loft, which was converted into the pottery showroom.

Bentham Pottery began production sometime in the late summer of 1976. Kathy was using the popular glazes of the time, namely, oatmeal and Tenmoku. In true 1970s style, she made lots of coffee sets and ploughman lunch sets as well as mugs, jugs, teapots, casseroles, soups, goblets and bowls. Kathy supplied people that ran “pottery parties”, which was a throwback from the 1960s, but extended into the 1970s, where a person would turn up at an organised pottery party with a load of pots to sell. I’m guessing it was like an Ann Summers party, but with pots (not that I’ve been to an Ann Summers party). Kathy also began to pick up craft shops in and around the area. Craft shops were very popular during the 1970s. Bentham Pottery supplied “The Road to China” at Barrow-in Furness and Ulverston, “Yorkshire Crafts” at Bolton Abbey, “Canalside Crafts” at Galgate, “Pottery and Pine“ in Skipton, “Hedgerow Crafts” in Silverdale, “Curlew Crafts” in Ingleton, “Dent Stores” in Dent, “Fat Sheep” in Reeth, “Watershed Mill” in Settle, Rievaulx Abbey, Dunham Massey, a chap that ran a pottery stall on Preston Market and many others . Kathy employed assistants to help her cope with the demand for pottery during this period. Joan Faraday worked full time in the late 1970s. Dorothy Harrison worked full time during the early 1980s, Stephany Kirkwood worked full time from 1982 until 1990 and Margaret Williams worked part time in the 1990s. In addition to producing pots, Bentham Pottery began selling clay and raw materials to other potters in the area.

During the first year at Oysterber Farm an event happened that we thought little of at the time, but have since come to realise was very significant. One day, we had a visit from an gentleman in his eighties called Richard Bateson. He turned up at the pottery with two children and asked Kathy if he could do some throwing to show his grandchildren what he used to do as a job (it should be noted that neither of his grandchildren showed any interest!) He then explained that he had run a pottery at nearby Burton in Lonsdale. Burton-in-Lonsdale, or Black Burton as it used to be known, had a long history of potteries and Richard’s family had been involved in pottery for several generations, producing all kinds of pots, but specialising in the production of stoneware bottles. Richard had begun work in his Dad and Uncle’s pottery at the age of 13 (in 1907) and had quickly established himself as a capable thrower. By the age of 16 he could throw all the wares that the pottery produced. Richard remained an amazing thrower – he threw with speed, precision and grace, transforming a lump of clay into a large vase, jug or bottle shape with a fluidity Kathy had never seen in any other thrower. Richard became a regular visitor to Oysterber Farm over that first year and was able to pass on his knowledge to Kathy, (particularly his collaring techniques for making bottle shapes) which she has, in turn, passed onto me. Richard passed on some of the traditional skills of the Black Burton potteries that could well have been lost with him as he ran the last of the Burton potteries and we remain very grateful to him for this.

Kathy, Paul and Lottie the goat outside the old Bentham Pottery. The Dutch barn behind was rebuilt to become the new Bentham Pottery.

Kathy found that the bottom shelf of the kiln fired colder than the rest of the kiln and the oatmeal glazes and Tenmoku glazes didn’t turn out well in this cold spot, as they underfired and looked a bit dry in texture and matt. However after a bit of experimentation, she found that a blue cobalt/rutile glaze did come out well on the bottom shelf. She applied a wax decoration to some of these blue pots in the same style as she used with her other glazes and the Bentham Blue range was born. The Bentham Blue gradually became our most popular range. It sold particularly well during the 1990s, especially after the magazine “Period Living and Traditional Homes” featured it on their front cover in 1995.

In the early days of Bentham Pottery the whole family got involved in making pots. My dad made cave lights (slab and coil built pots which had stalactites and stalagmites and were back lit with an electric bulb), slab built plant pots and wall hangers, small farm houses with barns and abstract repeat decoration wall hangers. My brother and I would make small clay animals, hedgehogs were particularly popular, as well as clay people such as Mexicans, Vikings and Daleks (I still make Daleks). We also used slabs of clay to make castles, houses and vases. My Nan, who lived with us, made some pretty anatomically incorrect sheep, they were really too wrong to call them stylised. Everything seemed to sell in the shop at the right price. It was certainly a valuable resource for making pocket money for my brother and me.

Kathy had noticed that one of the estate agent’s windows in Kirkby Lonsdale was not being used for any display purposes. She approached them and asked if she could display some of her pottery in the window to advertise the pottery. The estate agent agreed to this. A catholic priest was visiting Kirkby Lonsdale, noticed the window display and then visited the pottery. The priest was involved in organising the papal visit of Pope John Paul ii to England in 1982. He liked Kathy’s glazes and wanted her to make 5000 bowls for use in Holy Communion for the papal visit. Kathy was a bit nonplussed with this to begin with due to the huge order size. Barrie came up with various lists, graphs and flow charts to prove she could actually do it in the timeframe, provided she stuck with the strict regime of output that his charts required and so she said yes to the order. Kathy’s helper at the time, Dorothy, through no fault of her own, then became ill and was off work during this busy period, which had unfortunate consequences for my brother, myself and my Nan as we were put to work weighing out the 5000 balls of clay to be turned into the bowls and also packing them. A lot of orders for craft shops were delayed that year due to this order.

In addition to running Bentham Pottery my parents also had goats, which Kathy milked, hens, Jacob sheep, one highland cow, sheepdogs and cats. My dad grew a lot of his own vegetables. My brother, Nan and I were actively coerced into all the jobs that are required with having all this going on. At times during my teenage years I felt as though I was living on a set from the “Good Life”.

My parents seemed to do stuff that none of my friends’ parents did, which was a strange mix of being cool and frankly abject embarrassment. When it snowed we were all walking up Ingleborough with skis on our back. We used to go roller skating as a family on the sea front at Morecambe. My dad built a 30ft yacht outside the Dutch barn. I can only guess he was now missing living on the coast. This resulted in numerous memorable encounters with the Irish Sea. When I say memorable I mean pot noodles, sea sickness and diarrhoea. My brother and I joined Young Farmers at Burton, and, to my embarrassment, my parents also joined the same club (to be fair to them they were probably still young enough to join). On project week at school I was staying at Bull Pot Farm, my parents turned up mid-week clad in lycra cycling gear (in the 80s) to say hello. One of my close friends is fond of reminding me of the time he came to our house for a meal. My mum cooked coq au vin and apparently I spent the entire meal whispering to him “I can’t understand why we don’t eat normal stuff, like egg and chips”I could go on, but this is meant to be about the pottery.

I answered the phone in the early eighties and found myself speaking with a gentleman from the BBC. He wanted to know if we would be willing to allow a camera crew into the pottery to record an episode for a game show called “Game for a Laugh”. I handed the phone to my mum and she arranged a date for this to actually happen. And so a BBC camera crew together with one of the show’s presenters, Sarah Kennedy (she was also a Radio 2 DJ), and two of the show’s contestants descended on the pottery. The initial idea was that the contestants were to make candle sticks on a pottery wheel. This idea however was quickly ditched after Kathy demonstrated making a candle stick. The producer thought it was far too phallic to be broadcast before the 9.00pm watershed. It was thus decided that the contestants would be taught how to make coffee mugs instead. When I say taught, I mean that in a very loose sense of the word. My mum did a demonstration and the contestants were straight in being filmed attempting to make the coffee mugs and predictably making a right mess of it, whilst at the same time producing excellent TV footage. Sarah Kennedy also had a go and managed to produce something that looked even more phallic than the candle stick Kathy had demonstrated (this footage was actually shown). What the contestants didn’t know though was that at the end of attempting the pots a wet suit clad caver , one Geoff Yeadon (of Underground Eiger fame)walked into the pottery and announced that he was going to take them to do another sort of potting, pot holing. They then were taken up Kingsdale and filmed crawling through Kingsdale Master Cave.

Margaret Thatcher came into power in 1979 and began the inevitable Tory cut backs in public sector spending, not to mention sky high interest rates. This eventually had a knock on effect for the economy as a whole, but particularly for the plumbing company that my dad worked for, as a lot of their contracts were for schools and colleges. My dad was made redundant in 1982. He decided that he would make use of the resources he had and his knowledge of working in the building trade and so decided to convert the farm buildings of Oysterber Farm into self-catering holiday accommodation. The pottery had to make way for this, so it was decided that as part of this rebuild the free standing Dutch barn should be converted into the pottery. Local builders Brown and Whitakers got the contract for doing this building work. As part of the deal, my dad negotiated that my brother and I would also be employed by Brown and Whitakers throughout the build. I think he thought working in the building trade would make men of us. It probably did. I certainly got to meet some real characters. My parents borrowed a lot of money to do this and took a huge risk. Thankfully though the risk paid off, as the self-catering accommodation proved very popular – bookings came fast and furious.

The kiln was moved once more by crane into the new pottery and production started once again. The new pottery was great – double glazing and cavity walls made for a much warmer environment.

After finishing my A levels in 1984, I really didn’t know what I wanted to do. I certainly hadn’t considered working at the Pottery. I went to Sunderland Polytechnic to study computer science, based on the fact that I had enjoyed A- level computer science. I very quickly realised that I didn’t want to work with computers. I visited the Art Department at Sunderland whilst thinking about alternatives and really liked the idea of the 3d design course that they offered, which specialised in glass and ceramics. I’d be lying if I wasn’t swayed by the fact that the ratio of girls to blokes on the computer course was something like one percent girls to ninety nine percent blokes, whereas on the 3d design course these figures were reversed. I quickly put forward a portfolio, which consisted of a few of the pots I’d made, my sketch book from O-level art days and went for an interview. Thankfully I was accepted onto the course and was able to transfer from the computer course. Reading between the lines years later, and with an understanding of how higher education works, I’m guessing they were lacking students that year and were desperate for bums on seats for funding purposes, so they were probably glad to have me, and as it turned out I got a good degree, so, despite the risk of me failing, it paid off for them. I graduated from Sunderland in 1987 and then worked at Sunderland for a year as Ceramic Technician for the 3d design department. I then went to work in a glass studio in Dorset, followed by a glass studio in New Zealand. I arrived back from New Zealand in the late 80s to a very recessed UK. I worked for my Mum for a bit, whilst I decided what to do next and as it turned out, never left!

The Craft Fair Years

Towards the end of the 1980s, a lot of the craft shops Bentham Pottery had supplied started ordering fewer pots or no pots at all. One of our main craft shops went out of business, the first we knew about it was a letter from a lawyer, inviting us to come and pick up what was left of the pots the craft shop hadn’t sold and hadn’t paid us for. I think there was a general move away from hand thrown domestic pottery at this time. Also the craft shops seemed to be selling more imported crafted items from various parts of the world which probably would have been a lot cheaper than buying hand crafted items from people producing things in the UK. Some change had to take place if I was to remain at the pottery and make a living from it. At the time Bentham Pottery also employed Margaret Williams on a part time basis. We could no longer just rely on wholesale orders from craft shops.

With this in mind, I drove around the North West for a few days with a suitcase full of our pots looking for potential craft shops/gift shops that would stock our wares. I didn’t have much success with this, but I did notice that everywhere I went there were posters advertising a craft fair at Ripley Castle. I ended up ringing the number on the poster and booking a table at the craft fair. We paid something in the order of £90 for this, which seemed extortionate at the time, however we sold £900 of pots. This was the catalyst for us doing craft fairs, on a regular basis over the next decade. During the nineties we averaged about 25 of these weekend shows per year.

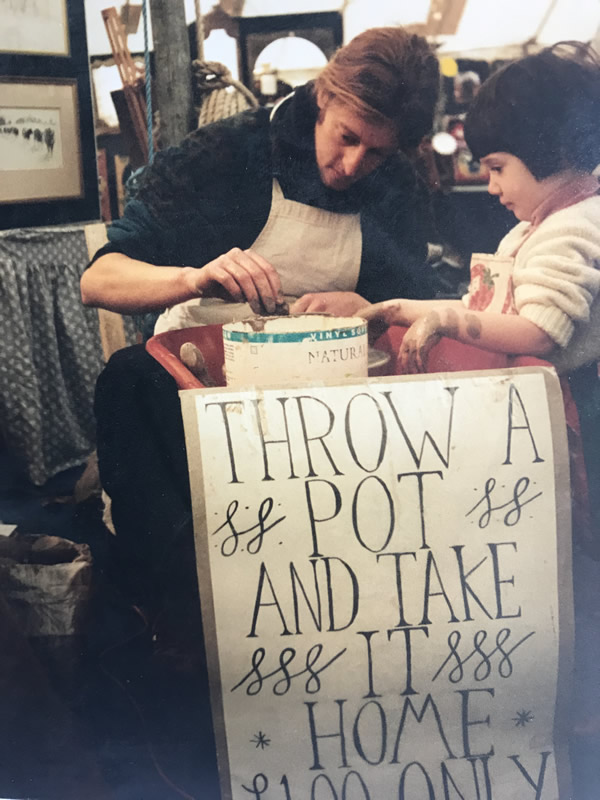

We’d fill the camper van with pots and food and set off all over the country, to such venues as Sandringham, Gatcombe Park, Harewood House, Windsor Race Course, Castle Combe Race Course, Epsom Race Course, Crystal Palace, Hatfield House, Missenden Abbey, Chepstow Race Course, Loseley Park, Capesthorne Hall, Newby Hall, Breamore House, Thorsby Hall, Castle Howard, Chiltern Open Air Museum, Burghley House, The Great Yorkshire Show to name but a few. We used to take a pottery wheel with us and in between selling pots we’d charge people to have a go at throwing a pot. We got very good at using other people’s hands like tools to make pots, so they thought they’d done it themselves!

The craft fairs were great venues for working out what sold and we were able to fine tune our products and get instant feedback (and ideas) from people. They were also bloody hard work, especially around Christmas time, when you’d get a number of fairs in succession, so you’d be arriving back from doing a show in London at 1.00am on a Sunday night only to be in the pottery on Monday morning to make stock/fill kilns for the next show!

We began fizzling out the craft fairs in the noughties. This was mainly due to increased orders of our named mugs, combined with an increase in the demand for teaching pottery.

Today, the only craft fair we continue doing from this period is Potfest in Penrith.

I’m not sure where the above two photos were taken; to be honest it could have been any of the venues. I’m guessing sometime in the mid-nineties?

Hyde End Craft Fair

My favorite craft fair tale from the 1990s was when my mum and I went down to do a four day show over the Easter weekend at Hyde End, near Great Missenden in High Wycombe. Had we read the craft fair organiser’s brochure sent to us earlier in the year we would have learnt that the Hyde End Easter show was, due to unforeseen circumstances, not occurring that year over the Easter weekend, but would instead take place one month later. Unfortunately, despite paying for the show in advance and receiving all the flyers for the show we hadn’t noticed this!

It’s difficult to describe the sinking feeling of realisation you have, when after spending the week before frantically filling kilns to have enough stock, loading the motorvan with boxes of pots, pottery wheel, clay, display stands and enough food for four days before driving the 6 hours down the congested motorways you finally arrive at the field where the marquees are meant to be up and buzzing with activity, only to find it empty. It was at this point that we read the brochure that the craft fair company had sent us earlier in the year. Bugger! We sat in the van in quiet contemplation.

Our options were really limited. It would have been great to have booked into a camp site and just had a mini-break. However this was not an option, as the motorvan was full to the brim with stock, so we wouldn’t even be able to get the beds out. Our only option seemed to be to do another 6 hour drive home. My mum was definitely not looking forward to the phone call to my dad, who had been left by himself to singlehandedly sort out a four cottage changeover while we were flogging dead horses up and down the motorway. This phone call though never happened and my dad is probably reading this tale for the first time now. (Hi Dad!)

We’d noticed a number of posters for a 4 day food fair at Chiltern Open Air Museum as we drove through High Wycombe. Chiltern Open Air Museum is a museum of historic buildings that have been uprooted brick by brick and reassembled on the site of the Museum. I knew the organiser of this show as they also did craft shows (some of which we did), so I figured it might be worth asking if we could have a stall there. I had no idea how pottery would sell at a food fair, but anything was better than another 6 hour drive on a bank holiday weekend. The only problem was that the organisers were arch rivals of the organisers of the Hyde End show, so I couldn’t just say that I’d turned up a month early for the Hyde End show by mistake and could I do your show instead? In the end we called in at Chiltern Open Air Museum and I lamely said that we were in the area with a van full of pots was there any chance of having a stall? The organiser was a bit bemused by this, mainly because we weren’t a food stall (thankfully he didn’t question me in any depth on what I was doing with a van full of pots miles from home), however the museum had just lent the organiser one of their buildings, for which they had little use, as all the food stalls were already set up in marquees and it was agreed I could use this. I managed to negotiate that I’d pay the organiser 10 percent of our takings, because neither I nor the organiser had any idea if we’d take any money at such an event. We thus spent four days that Easter selling pots from a 1930s prefabricated wooden school house. Cliff Richard turned up at the show as a customer, he didn’t buy any of our pots though. We actually ended up doing well, so much so in fact that we did it again the following year. There was probably too much food and people were just glad to see a different stall. We arrived home late on the Sunday night after a 6 hour drive up the motorway and nobody was any the wiser! One month later we made a return to Hyde End.

The craft fair that literally blew down!

In the mid-nineties, a craft fair at Ripley Castle came to a sad end!

We’d done good trade on the Saturday and set off from home early Sunday morning. The fact that the wind was blowing strongly didn’t really register with me as a cause for concern. This view however rapidly began to change on approaching the show ground. I noticed in the fields before Ripley Castle that an excessive amount of bags and wrapping paper had been blown and stuck onto the wire fences making an interesting multi-coloured montage. On closer inspection of this random work of art I noticed that a large proportion of the bags were our very own Bentham Pottery bags with “Bentham Pottery” inscribed in large bold black letters! Littering the entrances of stately homes wasn’t the way I’d envisaged the bags would be used as part of our advertising campaign. Arriving at the marquee the full extent of the horror unfolded before us. The marquee had gaping holes in it and was swaying ominously. The wind was literally lifting sections of the wall of the marquee up 15ft into the air, only to be dropped down to the ground again and then lifted again.

I spoke to some of the stall holders that had camped on site and discovered they had been up since 1.00 am, armed with mallets, stakes and guide ropes attempting to save the show. By 3am, the battle was lost and the wind literally opened sections of the marquee.

There were firemen on site that strongly advised us not to go in the marquee. However given the fact that I was doing a fair on the next weekend and all our stock was currently in a disintegrating tent in front of me, not to mention our display, backdrop lights and pottery wheel, we decided to ignore this warning and so in between the marquee lifting up and down, we packed our pots and did one of the fastest show break downs of all time.

Remarkably we lost very few pots. Other stalls faired far worse. People selling paintings and print lost virtually everything.

I’d like to say that this never happened again, but it did. Twelve months later at Whitworth Hall, County Durham. Around mid-day on the Sunday, strong winds caused the cross member beam of the marquee to break in two and start flailing around inside the tent. This was immediate cause for a fast evacuation. The sides of the tent were taken away to release the wind pressure. At the time that this happened, I had a line of customers who then proceeded to help me pack boxes and carry them to my van (God bless the Geordies). One elderly gentleman picked up our pottery wheel and carried it single handedly. I then continued doing business from the back of our van.

Named Mugs

The two things that have kept Bentham Pottery in business since the millennium are named mugs and pottery courses.

Kathy has made named mugs from the early days of Bentham Pottery. Her technique had been to roll out a strip of clay, stick it onto a mug and then using individual letters, she would stamp the name into the clay. This technique worked fine, providing the name was short. She used to do a lot of mugs with “Dent” on for Dent Stores, which was relatively easy, as it was only four letters. She also did a lot of mugs for the outdoor centre “Castle Head Field Centre”, this was time consuming, as it meant stamping 13 letters into the clay strip (she actually used two clay strips to do this). After watching Kathy laboriously producing “Castle Head Field Centre” mugs, I came to the conclusion that the process was way too time-consuming, boringly repetitive and inefficient, so I decided to use some of the casting techniques I’d learnt at college. I made a blank disc of clay and spent a fair amount of time carving “Castle Head Field Centre” around the edge of the disc and was able to carve their logo in the centre of the disc. I then cast plaster of paris over the disc to create a repeatable sprig mould. Clay could then be pressed into the sprig mould to produce the name and logo on a disc of clay that could then be stuck onto the mug. This revolutionised the whole process, as it meant complex images and text could be reproduced with more speed. The only time consuming bit was making the sprig mould in the first place, but this didn’t matter as much if there were hundreds of mugs to make. My first sprig moulds weren’t great, but I rapidly improved with each one that I made. I started to use different materials, such as latex to get finer detail in the mould. Orders for named mugs slowly increased during the late 1990s. I can’t remember the first named mugs we did for a fell race, but in a very short period of time we seemed to be making named mugs for every Fell Race in the Lake District and some in Wales. Businesses began ordering named mugs, as well as craft shops, tea rooms, University departments, society’s, conventions, commemorations and tourist attractions. We still continue making our usual range of pots and one-off items, but the named mug has become the “bread and butter” pot of Bentham Pottery over the last twenty years.

Pottery Courses

There has always been a demand for pottery courses at Bentham Pottery, Kathy occasionally taught people in the 1970s and 1980s. I did a basic teacher training course in the early 1990s. The course was organised by Craven College and as part of it I had to do 30 hours of teaching in a classroom, some of which would be observed. I was wondering how and where I was going to do this when one of Craven College’s existing ceramic tutors suddenly pulled out of an adult evening pottery class they were meant to be teaching at Ingleton Middle School. I took over the class. There were few facilities for pottery at Ingleton Middle School. I brought in all the clay, pottery tools and even wheels on a weekly basis. I took all the wet pots and equipment back to the pottery where the pots were then fired. I remember one evening being pulled up by the police on the way home from a class. The policeman wanted to know why I was travelling so slowly. I opened the back of my van and showed him the tall wet coil pots and explained to him that I had to travel slowly or else the pots would collapse. I taught at Ingleton Middle School for a few years before some builders doing renovation work in the classroom discovered asbestos. Craven College rang me and told me they would have to cancel the class whilst the asbestos was extracted. Rather than do this I suggested to them that I teach the class at the pottery. They agreed to this and even agreed to pay us rent for the building, which was an unexpected bonus and so the class moved to Bentham Pottery and never actually returned to Ingleton Middle School. A major upheaval had to occur at Bentham Pottery to accommodate the 12 people attending this class. We had a major throwing out session and managed to find some old tables to increase the available working space. Teaching the class at the pottery made my life a lot easier, as it meant everything was now in one place and I was no longer transporting wet pots and pottery wheels around the countryside.

In the late nineties Craven College asked me to teach their full time (further education) students at their main campus in Skipton. This meant teaching 16 to 18 year olds doing foundation courses in art and design. These younger students were initially a bit of a shock to the system for me, as they were very different from the keen adult students in the significant fact that not all of them were that bothered about learning pottery! Initially I taught a morning class and then worked as a technician in the afternoon mixing glazes and filling kilns. Gradually though, I was given more days teaching. I even ended up teaching Stage Set Design, a subject which I might hasten to add, I knew next to nothing about! I’m not quite sure why the “powers that be” at Craven College though a potter would be good at designing stage sets? All I can say is teaching a subject that you know little about to twenty or so 16 year old performing art students was a very steep learning curve!

After a few years of teaching the full time students at Craven College, I was informed that my teaching certificate was no longer valid for teaching in Further Education and that in order to continue I would have to attain a fully blown Post Graduate Certificate in Education. I duly enrolled on the part time PGCE organised by Craven College and Huddersfield University and got this qualification. I discovered that Craven College seemed to have a policy of continually moving the goalpost, my O levels in maths and English were suddenly no longer deemed as legal currency and I had to do Craven College’s own English and Maths exams every three years, to prove I was up to the job of teaching pottery? Curiously, they never actually tested my ability to make pots.

Around the millennium, I set up a website for Bentham Pottery. I had no idea at the time, of the significance the website would have on our future business, particularly pottery courses. I advertised pottery courses on the website and course enquiries began to trickle through via the contact page.

By the mid noughties I was teaching two adult education classes at Bentham Pottery organised by Craven College and teaching 1.5 – 3 days a week (term time) further education classes in Skipton at the main Craven College campus. In addition to this we were teaching private pottery courses at Bentham Pottery, increasingly booked via the contact form on our website. Teaching was definitely becoming a larger part of my income.

My dependency on Craven College for providing me with regular teaching hours was about to change though. Adult education classes began to experience harsh cut backs from the millennium onwards. Art classes were particularly badly affected. By about 2005, Craven College’s once thriving adult courses had all but disappeared. I somehow managed to hold out with my classes until 2008, when funding for them was finally stopped. This culling of adult education classes happened countrywide and was, I felt, a loss to the country as a whole, as adult education not only provided an affordable opportunity for people to further their education but they were good for social interaction and well-being. Faced with the closure of my adult classes, I decided to attempt to run one of them privately, after all we did have the classroom and equipment and I knew all the students. The transition to running the class privately was seamless, my students were happy to join a privately run pottery class and the class is still running to this day. One of the huge advantages of running the course privately was there was no more paperwork, registers, assessments & feedback, external and internal lesson inspections and pay claims.

Fortunately educational cuts didn’t affect 16 to 18 year olds (further education classes) at this time, so my day time classes at Craven College campus in Skipton were still secure. However this was about to change!

In 2008 the American banks discovered that selling mortgages to people that couldn’t pay them back once the fixed interest rates period had ended was not a good idea. The resulting 2008 world banking crisis caused by these default payments forced the government to bail out the banks. This meant there was suddenly a lot less money for the public sector. Further education, long the underdog of the educational system, was badly affected by cuts in government funding. Part time tutors like me without permanent contracts were particularly vulnerable. Between 2008 and 2015 part time tutors hours were cut every year until 2015, when there were no more hours left to cut and so my 20 years of teaching classes at Craven College came to an abrupt end. Nobody from Craven College actually told me I had lost my job; I just didn’t receive the usual email in July, to let me know what hours I’d be teaching from September 2015. However, by the time that this email didn’t arrive, a major ceramic event had happened that meant I had more work than I could cope with. I feel that one of the advantages of further education, as opposed to say going to a sixth form college, is that students get taught by part time tutors who actually do real work in the industries that the students are interested in, this largely came to an end in 2015. According to The University and College Union between 2010 and 2017 more than 23,000 posts were lost in further education colleges in England, amounting to a third of the teaching staff overall.

In life, when one door closes another door can sometimes open and the door that opened for us in 2015 was a BBC Two programme called “The Great Pottery Throw Down”. “The Great Pottery Throw Down” pitted amateur potters against one another, with various tasks and skill tests with one prospective potter being eliminated each week, until a final winner was declared. The show was a massive hit. When the series ended in early December, people began looking for a pottery experience gift to give to their partner/spouse, who had keenly watched every episode of the “Throw Down”. For once in our life we found ourselves in the fortunate position of being in the right place at the right time with the right product and very little competition (there were only a handful of pottery throwing classes in the country at this time). Pottery course enquiries from the contact page of our website went through the roof. Glad as we were for this business, the administration of all these course bookings and enquires became a nightmare. I was coming home from the pottery after rushing around all day making the pots needed for our Christmas orders, only to then spend the entire evening answering emails to people interested in courses. My wife Jenny had taken a week off work in mid-December to get ready for Christmas and she spent the entire week answering course enquiry emails for me. She set up a database and outlook shortcuts to make this whole process a lot easier. Unfortunately (for her) she did this so well and efficiently that she became a fully unpaid up member of the Bentham Pottery team and she is still doing it to this day.

We did an excessive amount of teaching in 2016, largely due to people who had watched the “Throw Down” and wanted to inflict the experience on their relatives. The trouble was that we were not used to saying no to any work, as in the past we were always glad for any work that came our way! I have since learned to say no occasionally. The second series of “The Great Pottery Throw Down” occurred in February 2017 and was followed by another wave of course bookings and enquiries.

We have always run half day courses and full day courses, but decided to run a week throwing course in 2017. The week course proved so successful that we ran 6 week long courses in 2018 and 2019. The “Great Pottery Throw Down” rekindled interest in the public for pottery. This seems to have affected the whole pottery industry, right from clay and raw material suppliers to the kiln and wheel manufacturers and potteries up and down the country. It has been a very welcome boost for the industry and with the forthcoming third series due soon, hopefully it will continue.

Jenny has asked me to add this to the account: In the early days of courses at Bentham Pottery our pottery skills and teaching ability were always far better than our admin skills. I remember on more than one occasion being half way up one of the three peaks on a Sunday afternoon and getting a frantic phone call from my Dad saying some people had just arrived at the pottery expecting a pottery course! I then had to run back down the hill, drive to the pottery, apologise for the delay and deliver a course in a state of semi-exhaustion & embarrassment. Thankfully, more common though than this was people arriving at the Pottery when I was working there to do a course that I had completely forgotten I was meant to be teaching. I’d usually be half way through throwing a large batch of mugs when this happened. Over time I developed an ability to outwardly show no sign of surprise and to act as though I was expecting them! Thankfully marriage seems to have completely solved this bungling, as when my wife Jenny took over pottery course admin, she introduced new systems to eradicate this problem. These include email reminders, mobile phone reminders via a phone app and good old fashioned verbal reminders on a daily basis.

The Bentham Pottery Brexit Mug

If Bentham Pottery ceased production tomorrow, then the one pot that we would probably be remembered for is our “Brexit Mug”.

The Brexit mug became a multi-media sensation in 2019 as the Brexit negotiations were taking place, going viral on both Facebook and Twitter, before the main news channels started picking it up and interviewing me.

The full Brexit Mug story is available here.

Covid 19

We had little idea what was about to happen to the country and the world in January 2020. I had been following the outbreaks of Covid 19 on the news and had become fascinated by the images of the virus. In the February I made a Covid 19 vase, based upon these images. I put a photo of it on Facebook. To my surprise I immediately started getting orders for them.

The full story of the Covid 19 vase is here.

Covid 19 had a devastating effect on Bentham Pottery. Craft shops that we supply were closed and events that we normally make named mugs for were cancelled. Pottery courses that had been booked months in advance had to be postponed or refunded.

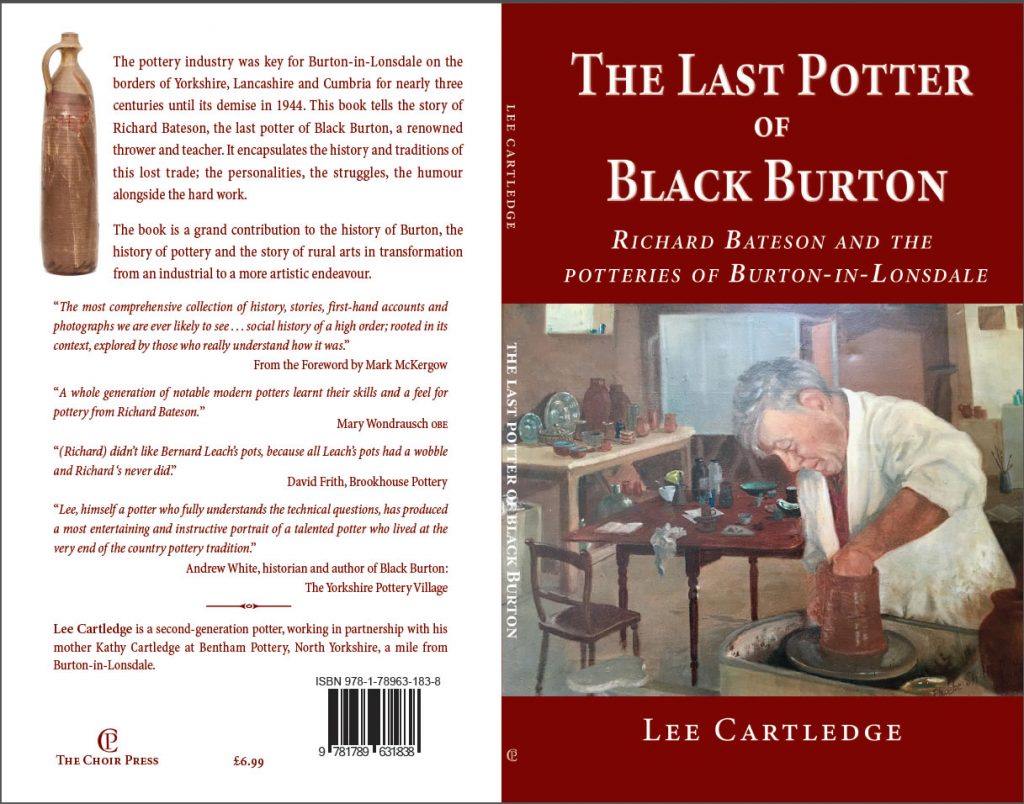

The Covid 19 vases helped us through the first lockdown. There was a brief return to normality albeit it with lots of social distancing over summer and then the second lockdown hit us. The second lockdown allowed our shop to be open with social distancing measures in place and I limited teaching to just two people at a time. However business was really quite slow and most people stayed away. I decided to start writing the story of the potter Richard Bateson around this time (Richard came into Bentham Pottery in 1977 and taught Kathy) . I did it partly because I had time to spare and also because I came to the realisation that if I didn’t write it then nobody else was going to and this was an ideal opportunity to do it . To my surprise I managed to get a publisher for the book and it came out in December 2020.